Rosalie Anderson Mixson Diary

1980-1994

By Rosalie Anderson Mixson

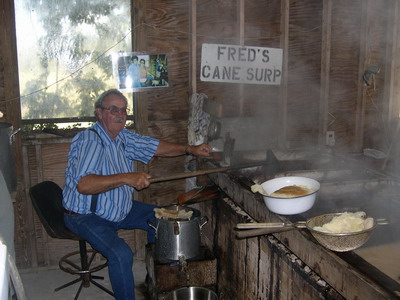

Cane: Grinding Cane and Making Sirup

First cane patch I remember was when I was about ten years old. We moved back from Bonaventure Fla. To our old home. Everthing had changed. Our old house was falling apart. The man had even planted corn in the front yard. The beautiful rose bushes were most all gone. There were several in front of the house, that was special, you could smell it all over the place when it bloomed.

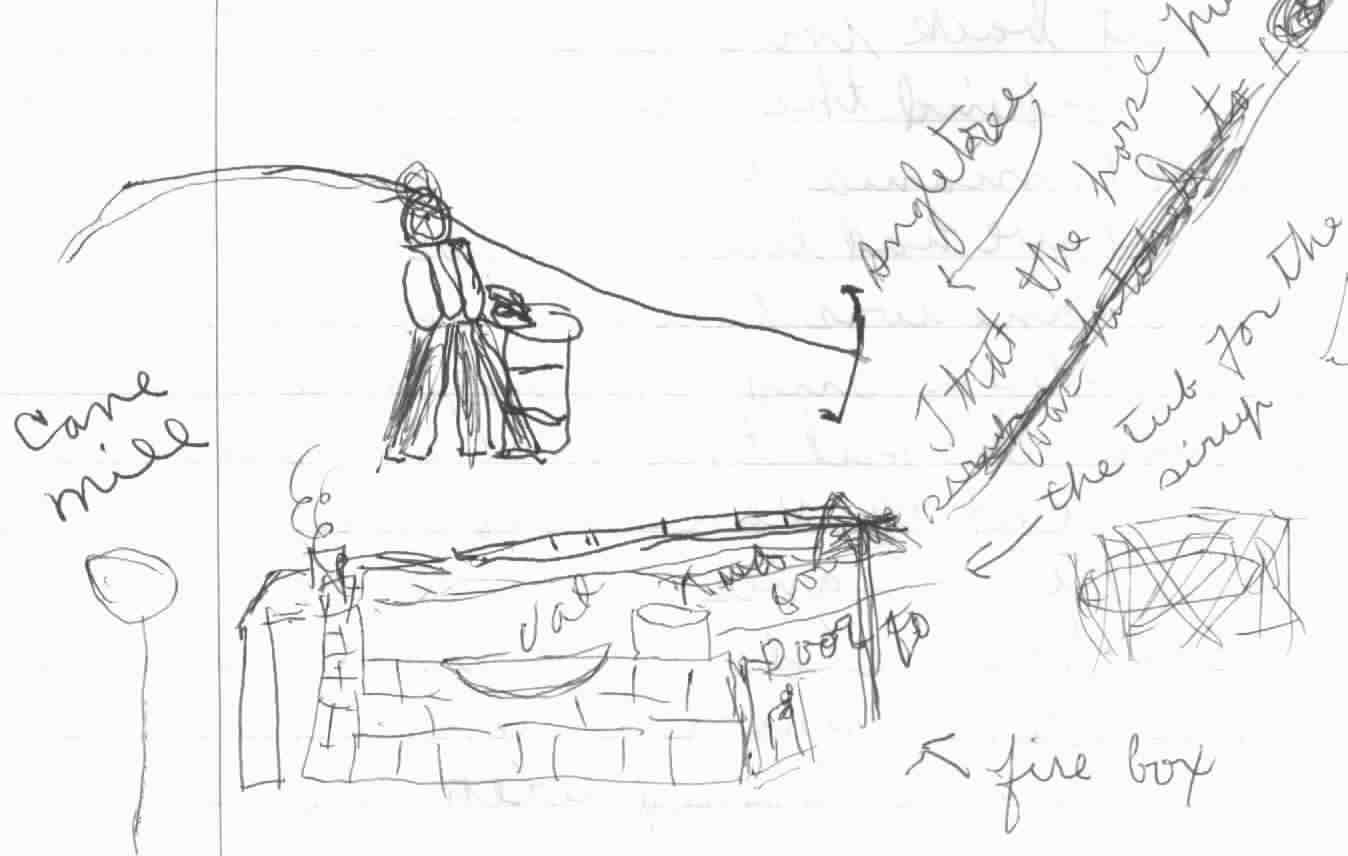

Out back was the cane patch, that is behind the new house where we slept, mama cooked in the old house that we had lived in befor moving. The cane was tall, taller than we children and a good place to play. About the last of October they cut the cane and made sirup. First the leaves were stripped with the back side of a long knife then the cane adit and piled in piles and covered with leaves called (fodder) then hauled to the mill. Papa had a cane mill in 1920 but first cane sirup that he made in 1910 he took to a neighbors to be made into sirup. At last he (Papa) got a mill with three rollers. It was on a stand made of large posts and had a long pole that turned the grinder. A horse pulled the pole around and around, while some one fed the cane stalks into the rollers that squeezed the juice out and then it ran into a barrel, the barrel had a clean cloth on top to strain the juice.

To plant the cane you cut the stalks into eighteen inch lengths or with two or three eyes (like potato) plant in rows three ft. apart and as close as you want the can in the row. My brother says the tope end of the stalk, that is what cut off the cane stalk that was made into sirup. The furnace that you cooked the juice into sirup was made with chimney at one end all out of rocks (sand) at one end was the door that the wood was put into like a fire place. In the middle was the cooker (or vat) when you had a vat full of juice someone had to stay by the vat and skim the skum of the juice, the better it was skinned the better the syurp (clearer) The skimmings were put into a barrel and fed to the hogs unless someone wanted them to make moonshine! We put a large galvanisd tin tub on the front of the furnace and when the sirup was done we strained it thru thick cheesecloth. Then put into bottles. To seal the bottles I used beeswax and pine gum melted together and poured it over a cork or a corn cob stopper.

Grandma's drawing of horse powered cane mill