1975

CIRCA

Work at CIRA was going well, and my boss gave me more responsibility one of which was the management of the remote batch stations. While the use of computer terminals connected to the main frame was increasing, most programs were still done on punch cards. With the increasing number of computer science students, submitting card decks and picking up printouts in the computing center lobby became unmanageable with 50 or 60 students typically in the lobby at all hours of the day. To address this the computing center purchased “remote batch stations” which they positioned around the campus. A remote batch station allowed for card decks to be read and printouts printed remotely from the mainframe which actually ran the programs. A remote batch station consisted of a minicomputer which had a card reader, printer, and card punch connected.

With the students in the computer science program being the largest group of users, one of the remote batch stations was installed in the computer science lab on the sixth floor of Weil Hall. My new responsibility was to ensure the stations worked, and if they had problems, resolve them. Some were simple, out of paper, card reader jams, printer jams, but the equipment was not all that reliable, and something was always breaking down.

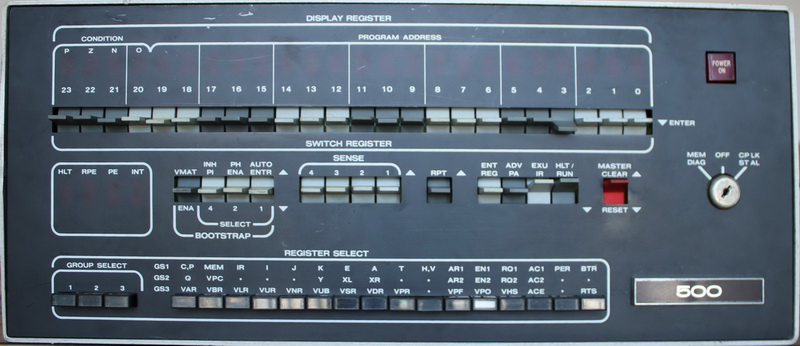

Harris 500 Minicomputer

The remote batch stations were made by Harris Corporation which is headquartered are in Melbourne Florida. So, any time there was a breakdown, my job was to call Harris support, report the problem an arrange for repair technician to be sent out. This was how I met Charlie the Harris repair technician.

Charlie was a couple of years older than I and looked like six feet tall, a slim surfer like body, with shaggy blond hair, blue eyes and a full beard. As a Harris service technician, Charlie’s service area included the University and with the remote batch station breaking down almost every week, I begin to see him regularly. Often he would come out, diagnose the problem, then have to return the following day with a part. If I wasn’t busy, I would often watch him do the repairs and before long we got to be friends, sometimes having lunch together if he didn’t have to rush to another repair.

One thing that Charlie and I talked about was electronics and the Altair computer which in the fall Charlie bought one and begin telling me about it. Charlie lived in Orlando and I drove down to see him a couple of times to see and work on his Altair system. Charlie was a hardware guy and I more software so I would help him with some of the programs.

1975 Data General Nova 1200 Computer

Another project I inherited was a custom remote batch station (RBS). Unlike the one from Harris, this was a custom RBS that was being designed and built by the head programmer, Mike, from what was the University Computing Center, then NERDC. I had first heard of Mike back when I was a student computer operator. Mike worked upstairs, he was like the Wizard of Oz, the master programmer. I would occasionally see Mike come down the stairs in the middle of the computer room, usually when there was some problem. Mike would sit at the console to the IBM 360 mainframe, flip switches on the console [picture] type things into the main console and the problem would be fixed. Later when I returned as a student programmer when it became NERDC, I would go to Mike for help on IBM 360 assembly language. Now I was working at CIRCA, Mike again was helping me. After the split of the NERDs and the CIRCUs, Mike’s pet project, a custom remote batch station, with to CIRCA while Mike remained a NERDC. So, I inherited Mike’s project and he spent some time explaining to me what I was getting.

A remote batch station needs a computer, the Harris RBS used a Harris minicomputer, Mikes RBS used a Data General Nova minicomputer. Data General was a lesser known computer company that did not last but its minicomputers looked much like the Harris and the more popular DEC minicomputers with lots of switches and lights. The Altair computer was based on the same design, switches and lights. Another thing all the minicomputers and the Altair have in common is they all at a basic level are programmed in the language of the machine, assembly language. While all machine languages perform the same task, instructing the computer what to do, each company’s minicomputer had its own unique machine, and thus assembly language.

Ok, my point here was not to go into the details of computing program but rather that Mike had written the control program for his custom batch station all in Data General Nova computer assembly language. He was nice enough to walk from the computer center building to my office in Weil Hall bringing dropping off on my desk a bound, three inch thick, 11x14 inch computer printout of the assembly code he had written for the RBS and then he took the time to review it with me. Over the next few months I would study it and begin to learn Data General assembly language.

Learning assembly language along with meeting Charlie would change my life the following year.

Updated: 01-15-2023